Exploring the Differences Between CO2 and Fiber Laser Cutting Machines

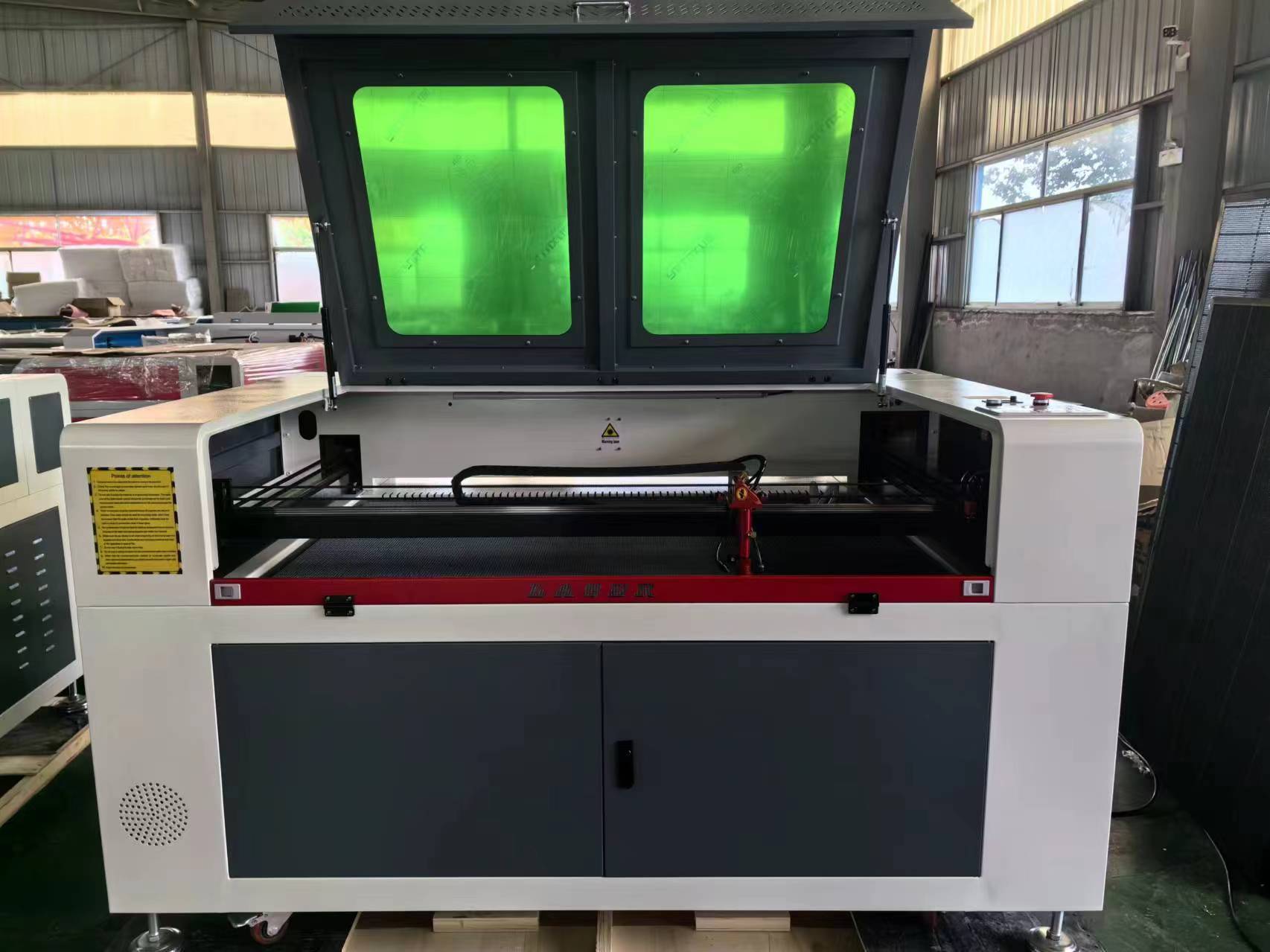

In the world of laser cutting technology, two prominent players have emerged - the CO2 laser cutting machine and the Fiber laser cutting machine. These machines have revolutionized the way materials are cut and engraved, making them essential tools for hobbyists and small business owners. In this article, we will delve into the differences between these two types of laser cutting machines, their application fields, and the future development directions of this cutting-edge technology.

Firstly, let’s explore the fundamental differences between CO2 and Fiber laser cutting machines. CO2 laser cutting machines utilize a gas mixture to generate the laser beam, while Fiber laser cutting machines use a solid-state laser source. The wavelength of the laser beam also differs, with CO2 machines emitting a wavelength of 10.6 micrometers and Fiber machines emitting a wavelength of 1.06 micrometers. These differences result in varying cutting capabilities and efficiencies, making each machine suitable for different applications.

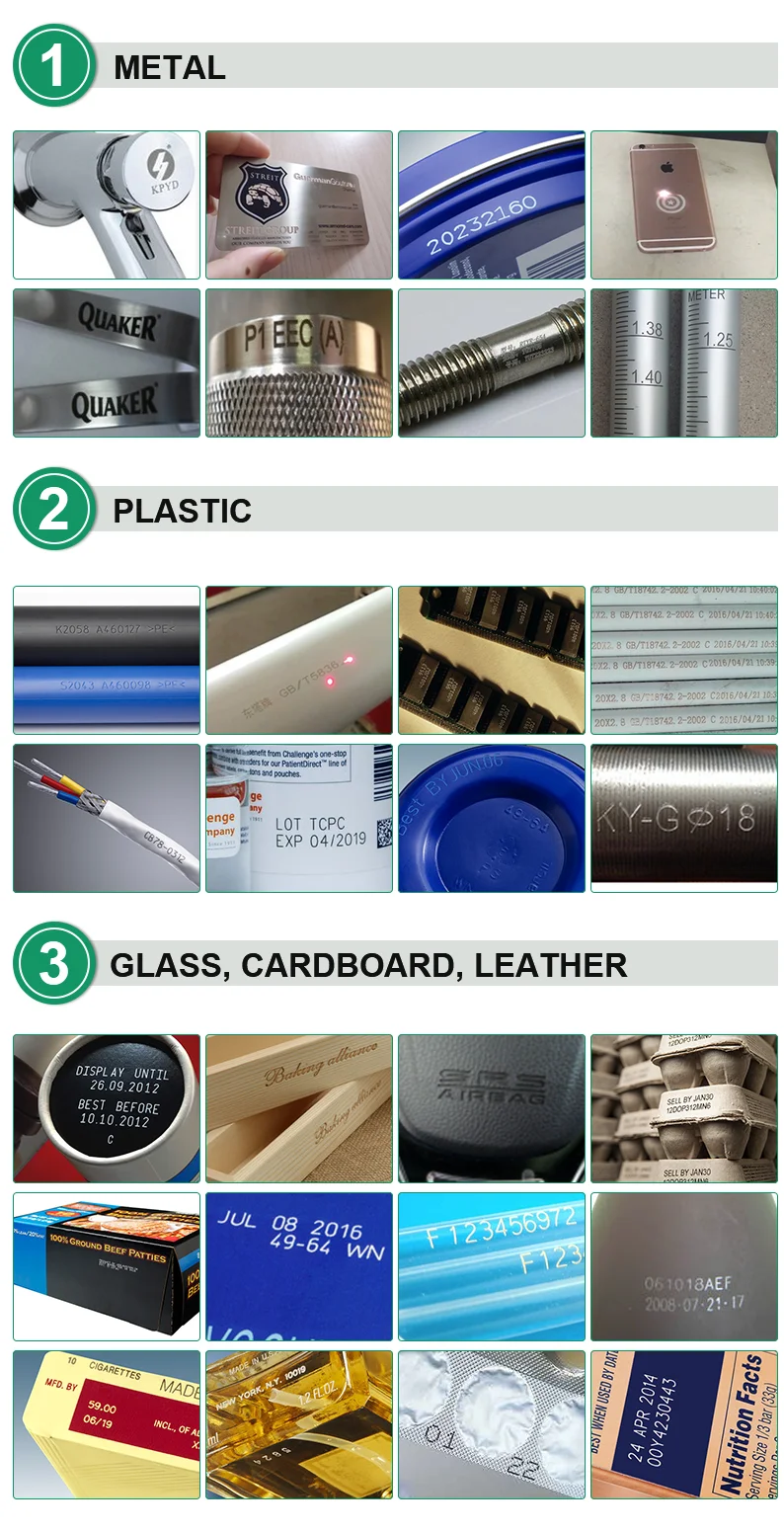

In terms of application fields, CO2 laser cutting machines are well-suited for cutting and engraving non-metal materials such as wood, acrylic, and plastics. On the other hand, Fiber laser cutting machines excel in cutting and engraving metal materials, including stainless steel, aluminum, and copper. The precision and speed of Fiber machines make them ideal for industrial applications, while CO2 machines are favored for artistic and creative projects.

Looking towards the future, both CO2 and Fiber laser cutting machines are expected to undergo significant advancements. The development of more powerful and efficient laser sources will enhance the cutting capabilities of these machines, opening up new possibilities for a wide range of industries. Additionally, advancements in automation and software integration will streamline the operation of these machines, making them more accessible to a broader audience.

In conclusion, the differences between CO2 and Fiber laser cutting machines lie in their laser sources, cutting capabilities, and application fields. While CO2 machines are suitable for non-metal materials and artistic projects, Fiber machines are the go-to choice for industrial metal cutting and engraving. As technology continues to evolve, both types of laser cutting machines will play integral roles in shaping the future of manufacturing, design, and innovation.

In summary, the CO2 and Fiber laser cutting machines each have their unique strengths and applications, and their future development holds promise for further advancements in the field of laser cutting technology. Whether you are a hobbyist looking to engrave intricate designs or a small business owner venturing into metal fabrication, understanding the differences between these machines is crucial in making informed decisions for your projects.